Installing the Highest Quality Synthetic Turf for Your Home, Business, or Sport.

What Makes Our Turf Surfaces the Best

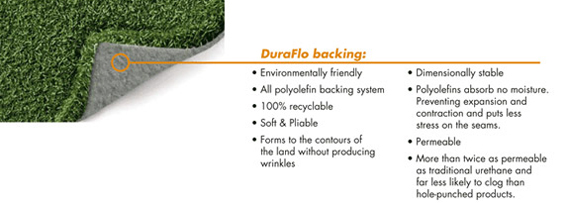

In an attempt to develop a synthetic turf program and is environmentally friendly in its use and its deposital, DuraFlo EEBS was created. DuraFlo EEBS stands for Environmentally Engineered Backing System, and have been recently developed to support soil structures for 100 years and beyond. DuraFlo's hot melt polyolefin adhesive systems has recently been perfected for use in the synthetic turf market. Aside from being 100% recyclable, Duraflo backing is more absorbent to moisture which prevents seem stress, and is also very permeable. Its an all polyolefin backing system which makes it environmentally friendly, and its soft and pliable so it forms to the contours of the land without producing wrinkles. Most importantly however is DuraFlo's drainage compacity, which means that the turf surfaces doesn't require the damaging hole punch process during installation.

Quality Installation for Long-Term Durability

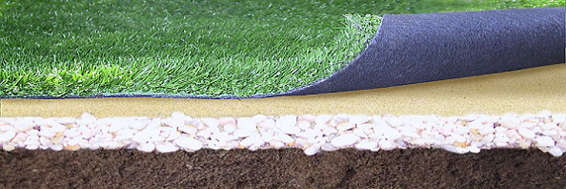

Our installation process begins with soil compaction, compacting the naive soil and removing water to prepare for installation. A crushed stone layer is then spread evenly over the prepared area. Vibratory and roller compactors are used to compact the stone layer to project specification. If necessary, a leveling layer is then added to ensure the surface is smooth enough to lay the turf surface. Next the DuraFlo turf layer is installed and seaming processing near the turf project near completion...

Plush Turf Solutions Click on the services link for more info

Contact Us

Copyright © 2011 - Plush Turf 365 - All rights reserved.